Willkommen bei

Schedl Automotive System Service

SCHEDL

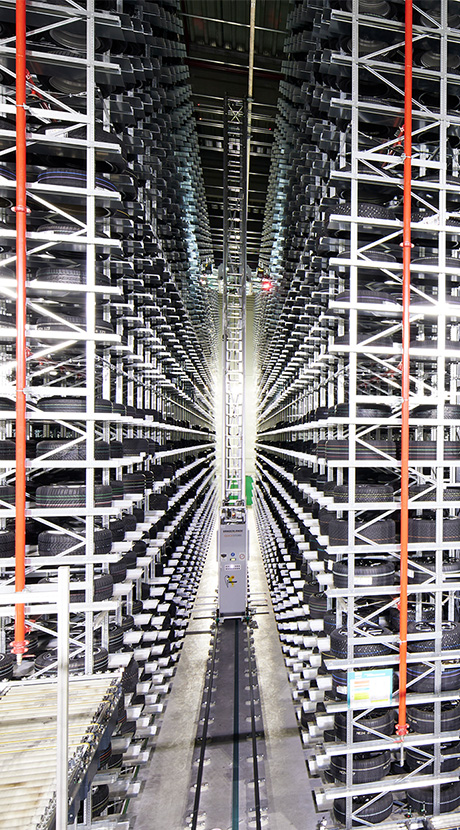

Just-in-Sequence Rad- und Reifenmontagen auf hohem industriellem Niveau sowie herausfordernde Logistikdienstleistungen sind unsere Kernkompetenzen – Qualität und Service bestimmen unser Handeln. Durch innovatives und nachhaltiges Arbeiten rüsten wir uns für die Zukunft in unserer Branche.

17 Mio.

17 Mio.

Montierte Räder pro Jahr

1000

1000

Mitarbeiter weltweit

30+

Seit über 30 Jahren Experte in der Komplettradmontage

DIE LÖSUNG

Von der Erstausrüstung bis hin zum After-Sales

Schedl ist Experte in der Montage und Logistik von Kompletträdern in der Erstausrüstung von renommierten Kunden. Zusätzlich betreuen wir unsere Kunden auch in dem After-Sales-Markt. Somit stellen wir sicher, dass der Markt auch im zweiten Schritt mit Originalware versorgt wird.

Kunden die uns vertrauen.

Komm in unser Team

Unsere weltweiten Standorte sind stetig auf der Suche nach neuen, motivierten Teamplayern. Dabei bietet Schedl dir, egal in welcher Lebenssituation, die passende Möglichkeit: Ob Ausbildung, Berufseinsteiger oder auf der Suche nach neuen Herausforderungen.

Globale Struktur

Dank unserer globalen Präsenz mit 14 Standorten in 6 Ländern auf 3 Kontinenten können wir jeden großen Automobilhersteller weltweit unterstützen.