Assembly

State-of-the-art and automated processes

With our state-of-the-art assembly lines, we perform fully automatic and seamless, complete wheel assembly in a highly professional manner and at the highest level of quality – from the receipt of the tyres and rims to delivery of the complete wheel to our customer. In doing so, we are able to adapt innovative complete wheel lines to the individual material flow of the respective car manufacturer at all our international locations: just-in-time or just-in-sequence.

Inspection and assembly

A visual inspection of the parts (wheels, tyres) and a temperature measurement are performed before installation. Then there is the choice of an RDC/RDK air pressure control system or rubber valve mounting, depending on the customer's preference. After mounting the valve on the rim, the tyre is mounted in the wheel assembly machine, which only takes a few seconds. Now comes the final mounting of the rim on the tyre, including torque monitoring. This is followed by matching, whereby a quality measurement performed for uniformity – depending on the customer's requirements.

Inflation and inspecting

n the second step, the tyre is precisely and repeatedly inflated in a special inflation machine in accordance with the customer's specified air pressure. To ensure maximum driving comfort for the end customer, the tyre fit on the rim is then optimised and inspected to ensure that everything meets the customer's required smooth-running characteristics. This is followed by an automatic reading and inspection of the RDC/RDK valves

Measuring and finalising

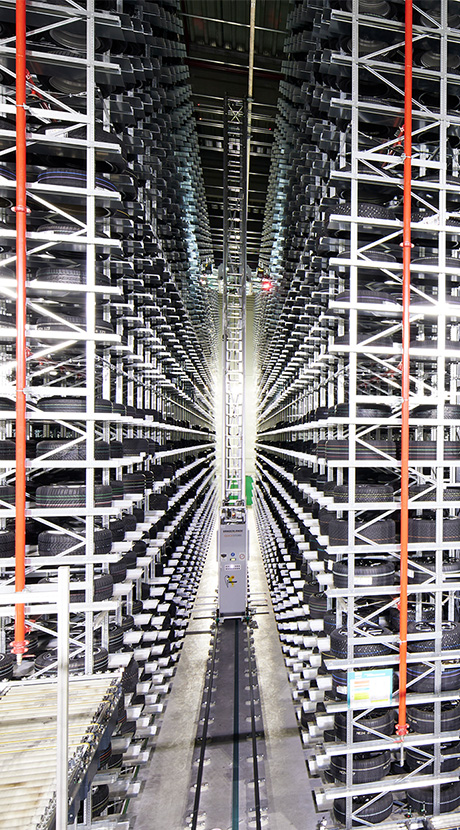

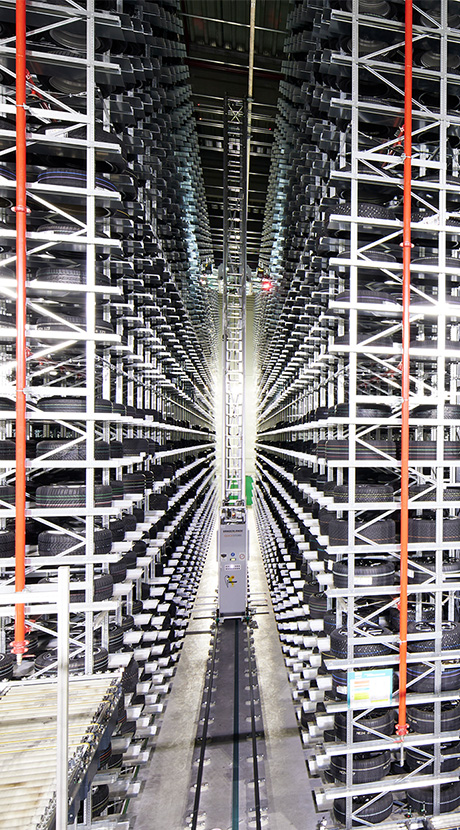

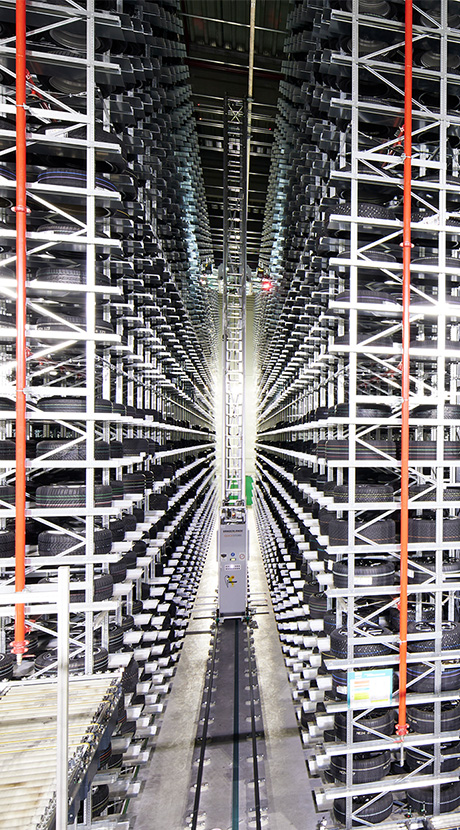

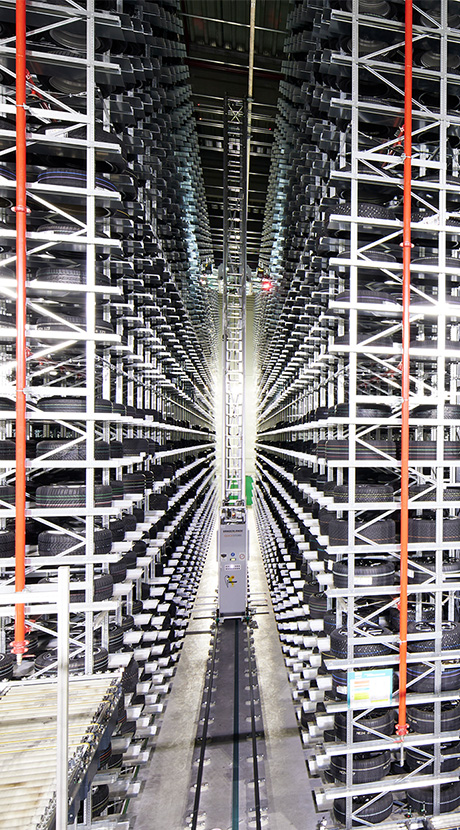

In the last step, the complete wheel's imbalance is measured. In addition, robots attach precisely calculated and cut balancing weights to the wheel. These are both impact and 2-part weights along with endless weights (coil). Now follows the residual imbalance inspection and measurement of the lateral and radial force variation (tyre uniformity), specifically in accordance with customer requirements. Finally, we carry out a camera-based conformity check and the final inspection. In this step, we inspect the wheel again manually for damage, conformity, etc. The finished wheel is now transported to a fully automated high-bay warehouse and delivered to our customer exactly in sequence and at the right time.

Inspection and assembly

A visual inspection of the parts (wheels, tyres) and a temperature measurement are performed before installation. Then there is the choice of an RDC/RDK air pressure control system or rubber valve mounting, depending on the customer's preference. After mounting the valve on the rim, the tyre is mounted in the wheel assembly machine, which only takes a few seconds. Now comes the final mounting of the rim on the tyre, including torque monitoring. This is followed by matching, whereby a quality measurement performed for uniformity – depending on the customer's requirements.

Inflation and inspecting

n the second step, the tyre is precisely and repeatedly inflated in a special inflation machine in accordance with the customer's specified air pressure. To ensure maximum driving comfort for the end customer, the tyre fit on the rim is then optimised and inspected to ensure that everything meets the customer's required smooth-running characteristics. This is followed by an automatic reading and inspection of the RDC/RDK valves

Measuring and finalising

In the last step, the complete wheel's imbalance is measured. In addition, robots attach precisely calculated and cut balancing weights to the wheel. These are both impact and 2-part weights along with endless weights (coil). Now follows the residual imbalance inspection and measurement of the lateral and radial force variation (tyre uniformity), specifically in accordance with customer requirements. Finally, we carry out a camera-based conformity check and the final inspection. In this step, we inspect the wheel again manually for damage, conformity, etc. The finished wheel is now transported to a fully automated high-bay warehouse and delivered to our customer exactly in sequence and at the right time.

Reliable sequential supply for your production facility

e will flexibly adapt to your needs. You decide whether you want just-in-sequence or just-in-time delivery. You can also choose between delivery in racks or via a containerless conveyor belt system (CBS). If you would like takeover of sequencing services for third parties, we at SCHEDL Group can do that for you as well.

Logistics

The focus is on excellent quality

Not least due to the high quality standard, we attach great importance to the complete traceability of data. Our quality systems are certified pursuant to IATF 16949 and meet all the industry's important quality standards. Even with increasing demands, you can expect reliable and continuously high quality. Complex supply chains are not a problem for us.

Quality

Reliable sequential supply for your production facility

e will flexibly adapt to your needs. You decide whether you want just-in-sequence or just-in-time delivery. You can also choose between delivery in racks or via a containerless conveyor belt system (CBS). If you would like takeover of sequencing services for third parties, we at SCHEDL Group can do that for you as well.

The focus is on excellent quality

Not least due to the high quality standard, we attach great importance to the complete traceability of data. Our quality systems are certified pursuant to IATF 16949 and meet all the industry's important quality standards. Even with increasing demands, you can expect reliable and continuously high quality. Complex supply chains are not a problem for us.

Reliable sequential supply for your production facility

e will flexibly adapt to your needs. You decide whether you want just-in-sequence or just-in-time delivery. You can also choose between delivery in racks or via a containerless conveyor belt system (CBS). If you would like takeover of sequencing services for third parties, we at SCHEDL Group can do that for you as well.

Reliable sequential supply for your production facility

e will flexibly adapt to your needs. You decide whether you want just-in-sequence or just-in-time delivery. You can also choose between delivery in racks or via a containerless conveyor belt system (CBS). If you would like takeover of sequencing services for third parties, we at SCHEDL Group can do that for you as well.

The focus is on excellent quality

Not least due to the high quality standard, we attach great importance to the complete traceability of data. Our quality systems are certified pursuant to IATF 16949 and meet all the industry's important quality standards. Even with increasing demands, you can expect reliable and continuously high quality. Complex supply chains are not a problem for us.

The focus is on excellent quality

Not least due to the high quality standard, we attach great importance to the complete traceability of data. Our quality systems are certified pursuant to IATF 16949 and meet all the industry's important quality standards. Even with increasing demands, you can expect reliable and continuously high quality. Complex supply chains are not a problem for us.